Traditional vs. Revolutionary

Traditional Suspension

Hot Works permits & cutting / grinding stations required

Multiple ascent & descent times on Lifts or Ladders

Increased Health & Safety risks

Logistics of getting parts to install locations (heavy / long lengths / crane / specialist equipment)

Time consuming & multiple tools required

Revolutionary Suspension

Up to 85% faster installation time

No measuring, cutting or grinding of steel parts

Simple to use & fully height adjustable

No Hot Works permit or cutting station required

Significantly less parts providing major cost savings on materials

Significantly reduced Health & Safety risks

Simple logistics on site

Are you suspending building services?

See the V.LOCK difference. Make the change

V.LOCK Suspension in 3 easy steps:

Secure the V.LOCK hanger to the structure (various anchor options available to suit different structure types).

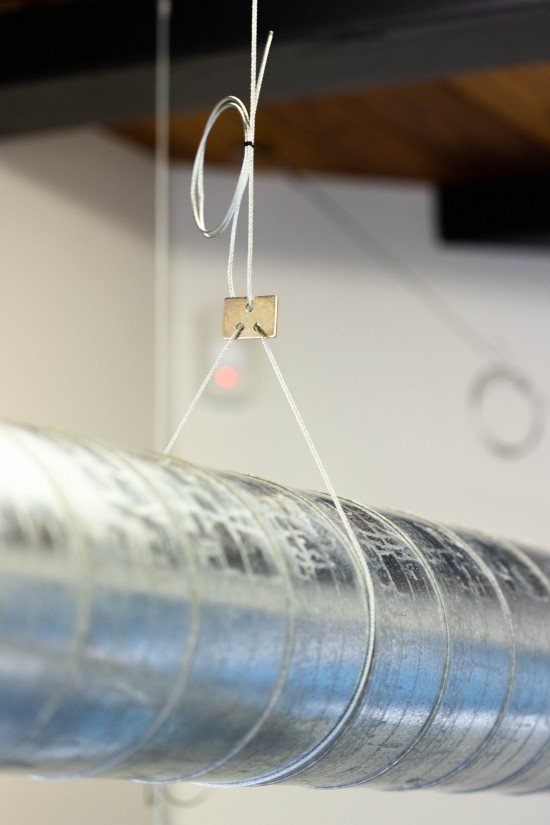

Loop the remaining wire around your services (duct, cable tray, trapeze, etc).

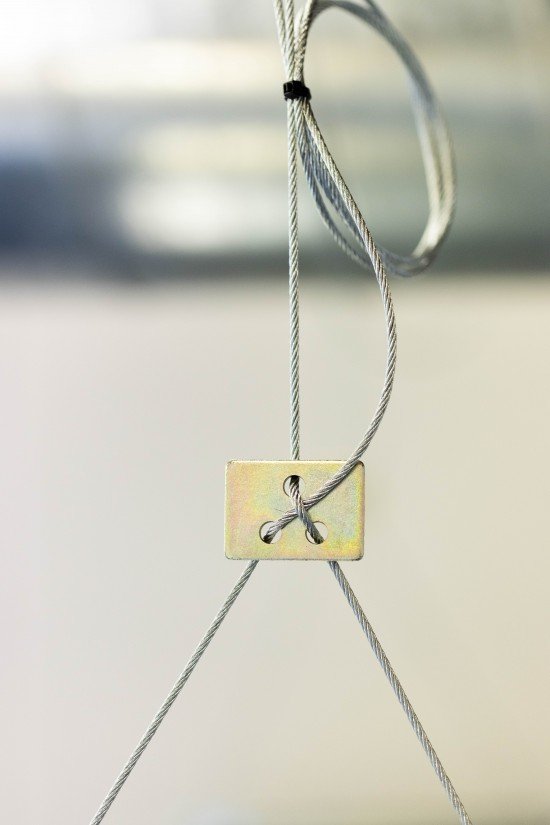

Create an adjustable loop with the V.LOCK plate and set at the desired height.

Job done.

LOAD RATED, TESTED & SPECIFIED BY INTERNATIONAL ENGINEERS

Download Loop End Spec Sheet

Download 90deg. Angle Bracket End Spec Sheet

Contact us here for a discussion, pricelist and sample

Call us on +64 3 310 6322 or email sales@vlockglobal.com

AWARDED AUSTRALIA INNOVATION PATENT IN 2021

OTHER PATENTS PENDING

New Zealand Registered Design No. 428629