Seismic Compliance of Non-Structural Components in Australia

Hosted by Amanda Rodgers of Engineers Australia, industry leaders Kayl Byrne, Structural Engineer from KCL Engineering, and Milton How, Director of Vaico shed light on Australia's Seismic Compliance for Non-Structural Components.

Don't miss this insightful discussion, part of the Thought Leaders Series in partnership with Conform Group, Australia's leading engineering firm specializing in HVACR platforms, acoustics, architectural screening, and roof access systems

This Webinar was held last 10 November 2022

Hosted by Amanda Rodgers of Engineers Australia, industry leaders Kayl Byrne, Structural Engineer from KCL Engineering, and Milton How, Director of Vaico shed light on Australia's Seismic Compliance for Non-Structural Components.

Don't miss this insightful discussion, part of the Thought Leaders Series in partnership with Conform Group, Australia's leading engineering firm specializing in HVACR platforms, acoustics, architectural screening, and roof access systems

Opening: Amanda Rodgers, National Corporate Engagement Manager, Engineers Australia

Good afternoon.

On behalf of Engineers Australia, I'm delighted to welcome you all to our Thought Leaders series looking at seismic compliance of non-structural components in Australia. My name is Amanda and I'll be your host for today. Firstly, in keeping with our custom, Engineers Australia acknowledges the traditional custodians of the country throughout Australia and recognizes their continuing connection to land, waters and community. We pay our respects to them and their cultures and to elders past, present and emerging.

Before we get started, I'd like to acknowledge that today's webinar is being hosted with Engineers Australia's industry partner, Conform Group. Conform Group is Australia's first fully-fledged engineering company for HVACR platforms, acoustic and architectural screening and roof access systems. Specialized in mounting mechanical equipment, Conform's expert team of in-house engineers and designers consult on requirements for projects. Their engineering services include certifying existing buildings to incorporate the solutions they engineer. They design, certify, manufacture, supply and install to specific requirements, including retrofits, new builds and upgrades.

Today we will hear from two speakers, followed by our live audience Q&A and I encourage you to send questions through to our speakers via the YouTube chat box.

I'd now like to welcome our first speaker, Kayl Byrne. Kayl is a senior structural engineer at KCL Engineering Australia, who specializes in the design of secondary building elements. This includes design for internal fit-outs, ceilings and partitions, overhead services, service risers, plant equipment and more. With a background in the structural design of buildings in Australia, Kayl also worked on structures for high seismicity regions in Papua New Guinea and the Solomon Islands. More recently, he has turned towards the Australian building services industry, catering to installations which up until recent years were overlooked from a seismic loading perspective. Please welcome Kayl Byrne.

First Speaker : Kayl Byrne, Structural Engineer, KCL Engineering

“Seismic Design of Secondary Elements”

Thanks very much for the introduction, Amanda. So I'm Kayl from KCL and we'll get straight into it.

Today we're here to talk about seismic design for secondary building elements, also known as parts and components as referred to in the code. So we'll go into that in a little bit more detail shortly.

We'll start off with a little bit of the sort of basics in the seismicity of Australia. Alright, so there is a bit of a sort of popular misconception and it definitely is a misconception amongst the general public and a lot of professionals, builders, etc, that Australia doesn't experience earthquakes or that they are negligible somehow. That's not the case.

That really is wrong and it's something that should be challenged and is challenged by the engineering industry. As engineers, we have a deeper understanding and it's important that that sort of gets out there and makes its way into the construction industry. So the focus today is on a part of the industry that's been largely overlooked for several decades and the last 10 years it's definitely improved and the last probably three or fouryears it's improved quite a lot. Still a long way to go ensuring seismic compliance, but today we can shed a little bit of light onto that.

So I've got a couple of graphics here on the screen. Just on the one on the left for the moment.

So Australia, the entire continent sits within its own tectonic plate.So we're not right on the edge of a plate. We don't have the border of two tectonic plates running through our country. What this means is we don't experience the extremely high earthquakes, sorry, large accelerations and large and high frequencies that other plate boundary regions do, places like New Zealand, New Guinea, Japan, etc. So some people might think that that means we don't have any earthquakes. It's not the case. We have quite a lot. They're quite frequent. They don't necessarily always occur in a populated area. So people don't necessarily think about it too much. So this is just intended as a bit of an indication. So that's 2016 marked in red and then the 10 years prior to that marked in yellow. And the maximum shown on there is roughly a magnitude 6 in the Antique.

So occasionally they do hit populated centres and that happened unfortunately in 1989 in Newcastle. So that was a magnitude 5.6 event and very significant cost to that, both economically and a human life cost unfortunately with 13 deaths there. And there has been certainly a response to that, but there were major structural failures, non-structural failures, masonry walls, etc. So what I want to sort of drive home here is that was a 5.6. Most people are going to be able to remember the Christchurch 2011, very severe, tragic event that happened was a magnitude 6.2 with a very high death toll and we'll hear a little bit more about that in the coming presentation.

Now that was a shallow, severe earthquake and that would sort of be considered something that is possible for an Australian city in a sort of a low likelihood. But the reality is that it will happen at some point basically. So we've got the Australian tectonic plate itself is in a state of constant compression. It's being forced together, crushed together by all the other plates around the edges. And what that means is eventually where there's some kind of fault line in the rock, eventually there'll be some slip or movement and a large amount of energy is released, resulting in ground shaking and displacements and accelerations for our buildings of all types.

So approximately at every 10 years on average, we're going to have a shallow magnitude 6 event, which could be quite severe at some location, very hard to predict where, and then just every two years, we're going to have a magnitude 5 on average. So these do occur and it's sort of a matter of if we have one to a population centre, the outcome from that would be quite severe. And really that's the purpose of what we're doing with our Australian standards and our seismic loading codes to take care of that.

Okay, so let's get a little bit more in depth onto that code itself.

Seismic Design Standard - AS1170.4

So after the unfortunate event for 1989, AS 1170.4, which most people would be familiar with, that is the Australian earthquake loading standard. Particularly structural engineers will know that one pretty well. So that was released in 1993 as a direct response to that event and much more rigorous code than had been in place before that.

And the following year, 1994, that's then referenced in turn into the then BCA, now referred to as the NCC, National Construction Series, or National Construction Code. So if anyone in the audience is not familiar with that document, it's extremely relevant for buildings, it's something that's good to be across.

So inside of that code, it tells us that all of our buildings, in order to be adequate and legal, they need to be designed in accordance with AS 1170.4. All right, so we'll go down that road a little bit further.

AS 1170.4, section A, clearly defines requirements for parts and components of buildings. So parts and components we also refer to as a secondary building structure. These present a risk to occupants and it's something that needs to be accounted for. So it's explicitly written there that it needs to be designed for horizontal and vertical earthquake actions.

All right, so before we jump into the specifics too much, let's talk a little bit about where the market is at with this type of thing. So to date, we've got all sorts of things that get installed into buildings and they may or may not have been considered for an earthquake event.

Okay, so the actual building base structure is and should be, and that's common practice, but there's a lot of things that then go into the buildings, which we'll go into more detail on that haven't really been considered properly. And that's improving at the moment. And a big driver for that is actually the insurance risk. So sort of at the top of the food chain, we've got insurers and the Australian sort of risk or particularly a major seismic event to Sydney or Melbourne is extremely large. There's a lot of existing building stock that wouldn't do too well, and that would have a pretty devastating impact. And that risk is actually reinsured overseas because the Australian industry is unable to accommodate that. So it's widely known, it's actually globally known in the insurance industry. And that's something that's sort of, that is a bit of a driver because the seismic risk is now being looked at with a closer level of scrutiny since the Grenfell Tower disaster and the whole issue with combustible claddings. So that sort of helped shine a bit of a light, particularly from the building certification point of view. So the building certifiers or surveyors, they're the ones who sort of enforce that engineering design is completed, and they're the ones that check to ensure the certificate that design has been issued. So they're a bit of a driver for seismic compliance actually being achieved. So the builders, they need to hand over that compliance to the certifiers before the building can be sort of deemed to be approved.

So they know about this seismic risk and they, or the requirements for design, and they typically pass that then on to their subcontractors. So all of the items we're going to discuss today, ceilings, petitions, building services, et cetera, they're generally installed by their own separate contractor or subcontractor. And occasionally there might be multiple levels of contractors. And so what the builder does is writes into their specification to the contractor that, "Hey, you guys need to achieve a seismic compliant installation." Those subcontractors may or may not really understand what that is.They're not structural engineers typically. So they're going to need some guidance from the engineering industry, which is a service that we provide.

All right.

So let's go into the actual specifics in a little bit more depth here.So I'm going to jump from this slide to the next a couple of times, but we need to define what is a part and component, what is this secondary structure? So pretty simple.

We can go to section 8.1.4 from 1170.4. And it gives us a very reasonably exhaustive list actually. So it starts off with some stuff under the architectural component designation. We've got walls that are not part of the sort of lateral stability of the building. So non-load bearing walls. We've got parapets, appendages, facades, et cetera. The connections of all those kinds of elements back to the base structure. Partition walls, floors, particularly sort of raised access floors, et cetera, and then ceilings. So the one I would pick out of that list there would be the ceilings is something that hasn't been adequately considered up until recent years. A lot of those other aspects are accounted for by the sort of base build structural engineer and have been done pretty robustly and rigorously in the past.

Often the partition walls have been designed for wind loads, which for a wall is typically going to be or is often the critical loading case. However, ceilings, particularly the in-plane loading from the seismic component of the mass is a bit of an issue. Something that's only just been gotten a handle on the last couple of years. And then we move on. So it also lists shelving and stacking racks.So come back to some of the sort of risk-based approach on that shortly.

And before we go into that next section, I just want to show a bit of a diagram here. This is taken from the Australian Ceilings Code, and it gives us a really good view into the kinds of components that are installed above the ceiling height. And these are typical things we're talking about here for today's discussion. We've got pipe work, we've got ducting, we've got lights, the ceiling itself, and the partition wall all suspended from a concrete slab, which is very typical for our market. We've got a fire suppression service there with either rigid or flexible connections. So just want to give a little bit of an idea of what it is we're considering.

So if we go back to that list, we've got mechanical and electrical components. This could be more summarised as building services. And there's a whole large list there of equipment that all needs to be considered for seismic load case. And a lot of these things, unfortunately, haven't been done particularly well historically. And that's something we're looking to improve, certainly improve.

So we get down to a bit of a list there. So ducts, cabling and piping distribution systems are all included. However, as marked in purple, we've got a list there, distribution systems individually supported except in the following situation.

So what that's saying is that that list there does not need to be considered for seismic actions. I'm going to go into a little bit more depth there.

So what it's essentially saying is giving us a little bit of a get out of jail free card, or that's the way it may appear on the surface, but they should be used with a bit of caution. So we'll dive into that a little bit more, I think.

Okay, I'll just reiterate that's from the Australian Ceilings Code.It's quite a rigorous code. I'll put that number up on the final slide for a bit of sort of anyone wants to do any homework into this area. It's a great, great resource.

Alright, so once again, all of these items here are going to be what we're directly discussing. Okay, so suspended equipment often installed overhead.

Alright let's zoom in on that list of exemptions. So this is something that comes up very frequently when we're in contact with subcontractors. From their point of view, getting seismic compliance might seem onerous or unnecessary. Again, they may not necessarily be aware of that seismic risk that we as engineers are. So it's very common for this part of the code to sort of be snipped out and applied in lots of different situations. So let's just run through it there. It's listing off essentially, firstly, structures in EDC1, so Earthquake Design Category 1. From those familiar with the seismic code will recognise that straight away.They are buildings that are deemed not to have a very low seismic coefficient. Then we also have small diameter pipe work for various applications, small sized air handling ducts, so HVAC duct, and also duct and piping distribution systems on individual supports less than 300 millimetres in length.

So we're provided with a little sort of cheat sheet there. I would, however, exercise a fair bit of caution because all we have to do is go back two slides and highlight it in red there. Life safety system components must be designed. If you look above that, we've got fire and smoke detection systems, fire suppression systems, they must be designed for seismic loads.

So this list here is only going to be applicable in certain applications. They don't apply to life safety systems and they certainly don't apply for importance level four buildings. We'll look into that importance level four side of things in a little bit more detail.

So coming away from this, our recommendation would be possibly if you've looked into this kind of area in any degree, really exercise a true sort of risk based approach with this. If you're going to use these exemptions, ensure that you've satisfied the actual life safety criteria of 1170.4. And that life safety aspect is something I want to iterate on.

Design Criteria - Life Safety Approach

So we'll move on to another slide and go into that slightly more detail as we have been continuing to do. Okay, so design criteria, a life safety approach. So that's how things are done in Australia for our buildings. I can highly recommend as reading material, if you're not aware of it, the commentary for AS1170.4 is very good. It sheds a lot of light onto what the code really means. And for any structural engineer or any engineer applying this code, very valuable to read through there.

So a lot of people might think that if we've constructed a building, it's all been done in accordance with the codes, that if an earthquake then comes along at some point in time, that the building's going to be just fine, it's going to withstand those loads. That is only the case to a degree in that it is intended to prevent structural collapse. It's not intended to prevent damage to buildings. So even a building that's been constructed today with modern methods and technologies, it may still need to be demolished after a design ultimate limit state earthquake. It's probably going to be severely damaged. This also applies for, so let's just run through this. We've got, we want to prevent against a reasonable margin against structural collapse, failure of parts and components.

So what we're looking at today, that would be life threatening to people in or around the building. So again, we've got that life threatening aspect and then failure of parts and components whose function is critical for the safe evacuation of people from the building. So these one, two, three points are things that we need to ensure happen as an engineer. So or do or don't happen. We need to ensure life safety and evacuation. So if an earthquake does occur, people need to be able to exit the building safely. Particularly if, you know, possibly a fire were to start up, something like that afterwards, people need to be able to get out in a pretty short amount of time.

All right. So again, it's very clear the design of structures along with this standard does not prevent damage. It's only there for life safety and minimizing risk. Okay. So when we're designing our systems, if we have this mindset of preserving life safety, we can really do a lot with that.

All right. So I mentioned importance level four buildings before. Focus on that slightly more here. So this is defined actually out of the NCC, which we discussed earlier. And it's clearly brought up in section 2.2 of 1170.4. Again, a lot of structural engineers are going to be aware of this, applying it to their designs.It's particularly important for building services and parts components as well. So the idea behind importance level four, so what we're talking about is hospitals, defence structures, etc., is to provide post-disaster functionality. So a building, a facility that can continue to function after an ultimate limit state or serviceability limit state event. We'll talk about that serviceability a bit more here.

So we've got for importance level four, a special study shall be carried out to ensure that it remains serviceable for immediate use following the design event associated with an importance level two structure.

So an importance level two structure typically would be a 500 year return interval. So what this is doing is it's presenting a serviceability limit state for a one in 500 year return interval risk level. So we can then apply that as an engineer to go and assess the importance level four items for an ultimate limit state, but also for a secondary serviceability limit state, which is not something that we do for importance level two and three structures. All right, so now the scope of that special study is actually quite large. It's not something we can fully cover today. So if this is something that you may be engaged in, the place to go again is the commentary for 1170.4. It gives quite a bit of guidance actually on how that special study can be conducted. It's a very, very useful tool, but essentially the goal is to ensure that serviceability.

Okay, So if we've got a hospital, particularly a big public hospital in a city and that city unfortunately experiences a devastating earthquake, that needs to remain functional so that people come and receive treatment. So things like oxygen for a patient to be treated, there's a little oxygen tap on the wall or the benchtop that's then connected to a pipe that runs through the building. That entire length of pipe needs to ensure that it can remain serviceable after that event.

So there's a lot of consideration that should go into that. So assessing the acceleration, displacements and associated lateral force that we're all aware of for a seismic event.

Concrete Anchors : AS51216:2021

Okay. So we'll switch gears slightly there. Something that's also critically important for our seismic design actually is what may on surface seem like a small part of it, the concrete anchor. So a lot of buildings we're dealing with on a day-to-day basis are concrete buildings. So beams, slabs, columns, et cetera. Very common for Australia, particularly post-tension concrete and the slabs. So when we're anchoring something, whether that's overhead equipment like we looked at before, it could be something that's anchored down to the floor or to a block wall, which is kind of similar. It's always anchoring or often anchoring to concrete. Now concrete's a bit of a special material because it's a composite between reinforcement steel and the concrete itself. And that concrete undergoes cracking under tension. So if a building experiences a seismic acceleration, it's shaking from left, right, up, down, parts of that building that normally would be in compression or in a state of sort of a fairly stable tension, it's actually going to be cycling through compression and tension through flexural effects or shear effects as the building is utilising its sort of lateral frame capabilities. What that leads to is cracks of various widths in the concrete itself as it's sort of experiencing that tension.

Now if we've got a concrete anchor that's in a zone of concrete that's under flexure and it's essentially it's cracking or predicted to be cracking through the engineering process, the capacity of that anchor is actually reduced quite a bit. And some anchors are not suitable for that application as in once the concrete cracks put into tension, it possibly could slip out even, in the worst case setting just fall straight out, which is something we certainly want to avoid.

So we are provided the Australian Concrete Fasteners Code, which I'll put up on the screen at the end, 5216. It gives us a bit of a categorisation here. So we need either C1 or C2 rated anchors. So anyone who's involved with the specification of anchors, please be aware of this and use it accordingly. It's something that can be achieved quite easily, it just needs to be looked at and needs to be followed up through inspection, QA etc. that the installers are actually using the correct anchors.

So a C1 rated anchor can tolerate a moderate crack width and that's going to be suitable for most applications. I've highlighted sort of what we consider to be most applications there.

And then for C2, which is mostly for importance level 4 structures or high seismicity structures, they are then suitable for basically a more rigorous testing standard for a larger crack width etc.

I'll give a little bit of an overview of the types of anchors to watch out for here. So on the left we've got the one, basically a 'do not specify' on the knock-in anchor. So this doesn't achieve a seismic rating. Unfortunately it is very common. They're used through widespread use throughout Australia and that's because this particular area is not, you know, installers, certifiers etc. are not always ensuring that an engineer gets involved.

Possibly some engineers may not be aware, but anyone who's here today, you're now aware we really need to watch out for what's referred to commonly as a knock-in anchor. So it's technically a displacement induced expansion anchor. So an internal plug is driven into a sleeve and that sleeve therefore expands and puts pressure on the concrete around it. Once the concrete cracks it goes into flexure through a seismic event. They perform very poorly. So the other two most common anchors, there are more, and if you're involved with concrete anchors go and have a look at the various manufacturers, see what they can supply. But typically we're going to use screw bolts or stud anchors.

Both of these can achieve a C1 or a C2 depending on the size and embedment depth. So you do need to go into a bit more depth there if you're specifying an anchor. The reputable manufacturers have software on their websites that you can use. That's typically quite good in my experience. And you can do hand checks based on AS52.16. But please ensure that you've got the appropriate seismic rating for the application. There's no point going and spending a whole heap of time engineering a suspended system, adding bracing to it as necessary, only to have all of those anchors fail because they were never designed for that purpose in the first place.

Alright, so on the topic of failure.

A colleague of mine from, the founder of KCL actually, took these photos. So again, this is drawing on some knowledge from the New Zealand side of things. A lot of our seismic engineering capabilities for Australia are sort of drawn from the New Zealand market.

Alright, so in 2013, significant earthquake for Wellington, unfortunately. And these are taken inside a fairly standard office building, magnitude 6.5 event. So this is showing pretty clearly a failure to assist sealing. So we've discussed the sealings a bit. We'll focus on them more because they're a bit of an area where still day to day I'll go to sites and see sealings that are not what we would consider to be seismic rated. They haven't had an assessment done or bracing and connections to deal with these forces and displacements. So it's definitely a lot of room for improvement on the Australian building market when it comes to sealings.

So we discussed earlier that life safety approach and evacuating a building. If you've got a ceiling, sharp metal objects falling down, covering the floor, people can't get out in a reasonable amount of time or injured or possibly killed as a result. That's not acceptable. That's not in accordance with the code.So we need to deal with that by designing with structural principles, designing the ceiling and also all of those other items that go in above the ceiling.

Design Solutions - Ceilings and Partitions

Ceilings and partitions, focusing on those ceilings again, we have the ASNZS 2785. Very good code from my opinion. It's got a lot of depth in there for seismic events. A lot has been learned from New Zealand and you'll hear a little bit more about that shortly.

So just the graphics on the screen here, a couple of just examples of we have a ceiling, so those smaller lightweight members you can see there. In the past it hasn't been considered. So all we need to do is assess the mass, assess the horizontal force component from the event as we would with any other building or structure and give it a load path basically. So bring it back to a load path assessment. Get that force into the base build structure. So we can do that through angle braces as you can see here in front of you. Nice efficient 45 degree angles. Not a big deal. We can install this pretty cheaply and really add a lot of resilience and capability into our installations. So that's dealing with ceilings.

Design Solutions - Building Services

On the services side of things, which is there's a lot of services that go into buildings, just as much money that gets spent on the base structure goes into the services as well. So once our assessment's done, we've analysed the system, we know what kind of seismic force we need to account for, we can then introduce bracing and we'll go into bracing in a little bit more detail very shortly.

These are just a bit of an example of the three most common types, particularly the one on the left there. We've got the tension cable brace, nice, elegant, very efficient from an engineer's point of view, we've got a 45 degree angle and a high capacity tension member. We can introduce that to create an effective load path back to the base structure. In the middle, we've got a tension compression brace with a strut added in. So not requiring multiple cables. And then we have on the right a rigid post type brace that's going to require multiple concrete anchors. These are all shown to a concrete, underside of a concrete slab, which is the most common thing we deal with in the Australian market. Sometimes it's steel or timber and we design those accordingly, but most common we've got concrete.

So, again, I'd bring it back to the tension cable braces is generally the most common tool for the job. You'll hear a bit more about the V-lock system very shortly, and it's a very efficient way of bracing these kinds of systems.

Okay. All right, so that's about it from me. Thanks very much for listening, spending your care and attention on this. Again, I'd reiterate those important key resources, AS1170.4, the earthquake actions in Australia. The commentary to that code equally as valuable. Again, we've got suspended ceilings and post-installed concrete anchors. So if there was only four documents, I would recommend it would be those four, possibly the NCC as well, if you're not familiar with it, any building engineer should be. Thanks again and look forward to some question and answers very soon. All right, we'll wrap that up. Thanks again.

End of First Speaker

Amanda: Thank you, Kayl, for your input. I'd now like to welcome our second and final speaker, Milton How.

Milton has over 20 years of experience working in the construction industry in New Zealand and Australia, and over a decade's experience in the seismic industry. Having worked on some of New Zealand's largest and most complex seismic projects, for instance, the Christchurch Justice and Emergency Services precinct, Milton and his team also worked on the seismic retrofitting of quake-damaged buildings in Wellington and Christchurch. With a deep understanding of the pain points of consultants, engineers and contractors, and the escalation that compliance brings, Milton can share his learnings of how to ease this transition. Please welcome Milton How.

Second Speaker: Milton How, Director, VAICO

“Topic: Seismic Compliance of

Non-Structural Components in Australia”

Good afternoon. Thank you, Amanda. It's a pleasure to speak to you all today. I'm Milton How, owner of VAICO, based in Christchurch, New Zealand.

So I had the experience of living in Christchurch and being in business supplying the mechanical, electrical, plumbing and fire service trades before and after the Christchurch earthquakes, the first being September the 4th, 2010. I've been asked to speak for a few minutes on my experience having lived through these earthquakes.

So I don't want to make too much of it or dramatise the events that happened, but just to try and give you an understanding of the true violence of any earthquake over six on the Richter Scale.

September the 4th, at 4.35am in the morning, the earthquake hit 7.1. I actually thought someone was trying to drive into my house on a bulldozer because of the noise and the violent shaking. I tried three times to get out of bed, but ended up back on it because of the ground movement. I had three little children who I was wanting to get to. I ended up crawling down the hallway to get to them finally. Then we roll forward to February, five months later, and the next big earthquake hit at 12.51pm, it was 6.3. Sadly, 185 people lost their lives. It was because of the time of the day and the fact that buildings were already weakened from the early earthquakes. I was at that time very close to the Canterbury Television building and spent over 24 hours on that site, along with the first responders. The sheer scalel of the devastation is overwhelming and it's well documented with photos such as these shown on the slide. When you think back on it, it's the little incidents that remain.

For example, we normally expect the police and the fire brigade and first responders to deal with these tragedies, but in this case they are overwhelmed. You'll notice in these photographs that maybe 10% of these people here are first responders.The rest are just normal civilians like you and me, risking their lives to help track men and women and children. There's no panic, there's no politics, it's just a willingness to do all possible to save lives.

I remember speaking to a policewoman, she was trying to stop the crowds of people running down a particular street. They were trying to escape the CBD. She had tears running down her face. I asked her what was wrong and she said there was a major gas leak down that street. She was trying to stop people going down, but no one listened to her. She had no backup. Then she also shared she had children at school and reports had come through the schools were damaged, but the communications were down, the telcos were down and not working. So no communication, she was upset. So everyone was affected.

But if we roll that into the talking about the contractors dealing with mechanical, electrical, plumbing and fire, very soon after this I travelled to Auckland, which is 800 kilometres north, and I was inspecting some hydraulic pipe which had been seismically restrained at a swimming pool. Just on the way out I said to the contractor, "What are you going to do about those filters?" These are floor mounted filters.

He said, "Mate, they won't move, they're like 200 tonne each."

I said, "The whole ground moves."

That's what people don't understand, the whole ground moves. So everything's got to be considered.

So just to go to the practical application of what these guys are dealing with on site, try and give some idea of the challenges they face, especially as the market's evolving and Australia and compliance is tightening up

VAICO V.LOCK x CON-FORM GROUP

We work with Conform, who's the distributor of our seismic bracing, V-Lock. It's the seismic brace of choice in New Zealand and becoming the same in Australia. So here we have four photographs showing damage at Christchurch Airport. The photo at the bottom left demonstrates the true violence of an earthquake with all the services destroyed. We had four major earthquakes, 56 were larger than magnitude five, and there was 14,000 earthquakes between September 2010 and June 2012.

Many of these you didn't feel, but a lot you did. As a side note, the suspended ceiling contractors were constantly being blamed for the suspended ceilings failing. These were repeatedly reinstalled with seismic bracing only to fail again. What was actually happening was the mechanical, electrical, plumbing, and fire services were swaying sideways and hitting ceiling wires, causing them to pull up, which in turn caused the ceiling tiles to fall out. So the MEP services were too close to the ceiling wires. This has now been addressed in the code.

In the top right, the photo shows horizontal clearances again not being adhered to and damage resulting of a duct trapeze hitting electrical cable tray. The bottom right photo is interesting. It demonstrates uplift, the force of the earthquake. As you'd all know, if a trapeze is braced horizontally and longitudinally and cannot move, the force must go somewhere, so it travels up. The M10 threaded rod is very strong under tension, but it's weak under compression, which causes it to bend.

I've also seen it snap clean off at the anchor point. This is a new concept to contractors, and it needs explaining to them why you need to rod stiffen the threaded rod in certain circumstances.

Codes and Compliances AS NZS 2758:2020 AS1170.4

Here's a clearance requirement chart published in the AS NZS code.

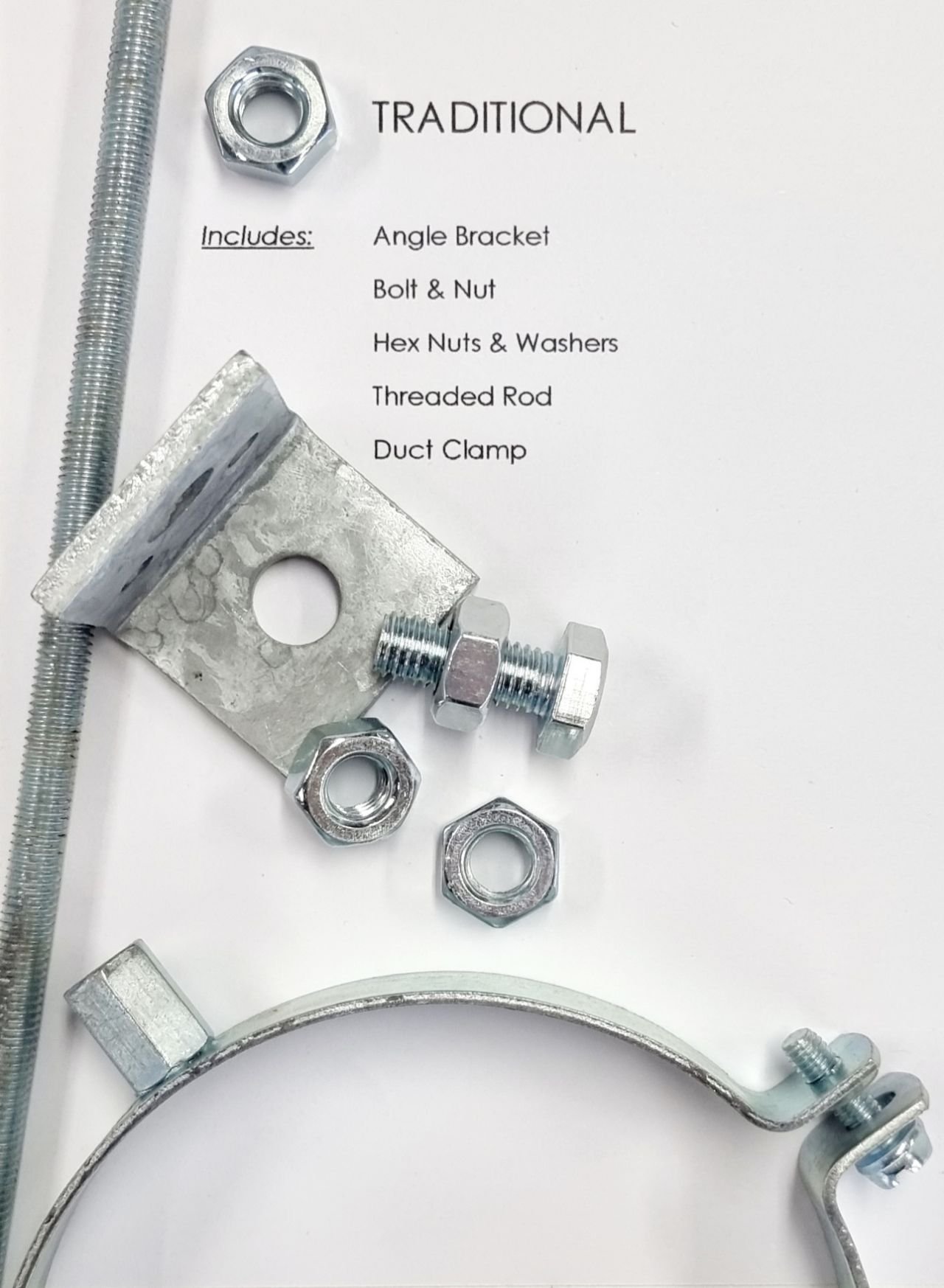

I would like to spend a couple of minutes going through the two different brace types.

There's solid and cable bracing, what the contractor's preferences are, and there's advantages and disadvantages to both types. So here's a valid installation location of a solid seismic restraint brace arm on a trapeze rack. So you have your vertical, your trapeze strut, you have your vertical support rod, your brace arm, but most importantly, the vertical support rod has been stiffened. Our standard methodology is to wrap the rod with a piece of strut. We have widgets that slide in and lock the rod up against the back of the strut, which essentially effectively forces the load path along the strut instead of the rod.

So now you've turned that rod into a compression post. So everything in the system has been sized correctly. The connection to the strut's been sized correctly, the strut is to be sized to take the seismic load path, the lower bracket, the brace arm, the upper bracket, and the upper bracket anchor. All of those things should be dictated within a proper seismic design. Any of the part of that puzzle that's missing that's provided by a seismic designer, without that piece of the puzzle, you don't have a complete design.

This next picture shows cable bracing used on cable, on tray and ducting. Now cable bracing only works under tension, so you have to put one brace north, you've got to put one brace south, so twice as many as solid braces which work under tension and compression.

However, as the market evolves, which New Zealand is probably five or six years ahead of Australia, the contractors start to insist on installing cable bracing instead of solid bracing wherever possible. Because even though they're putting in twice as many braces, it's four or five times quicker to install. So their biggest cost on site is labour. So that's their preference.

Also logistically it's much easier to say put 200 braces on your scissor lift of cable braces and just install them. Whereas if you're doing solid bracing, you've got to go up and down, cut, grind, measure to get the 45 degree angle, let alone getting a pack of six metre lengths of strap up onto the fifth floor, you get the picture.

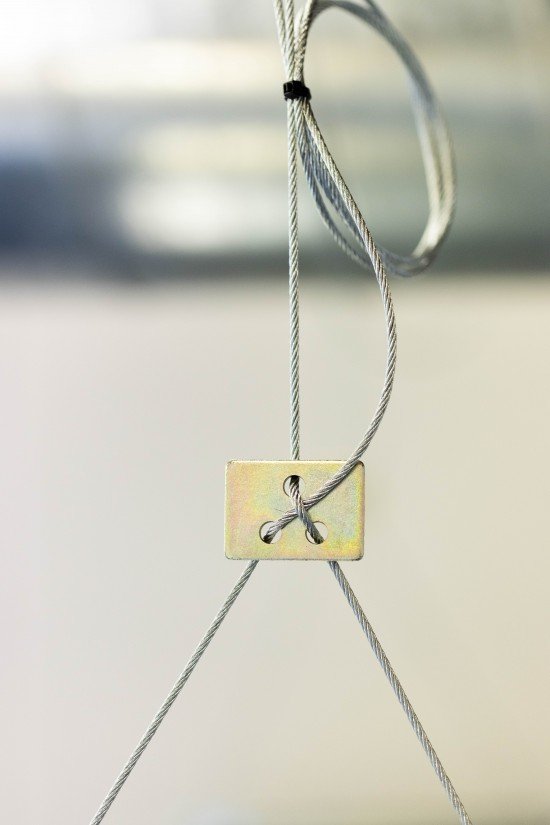

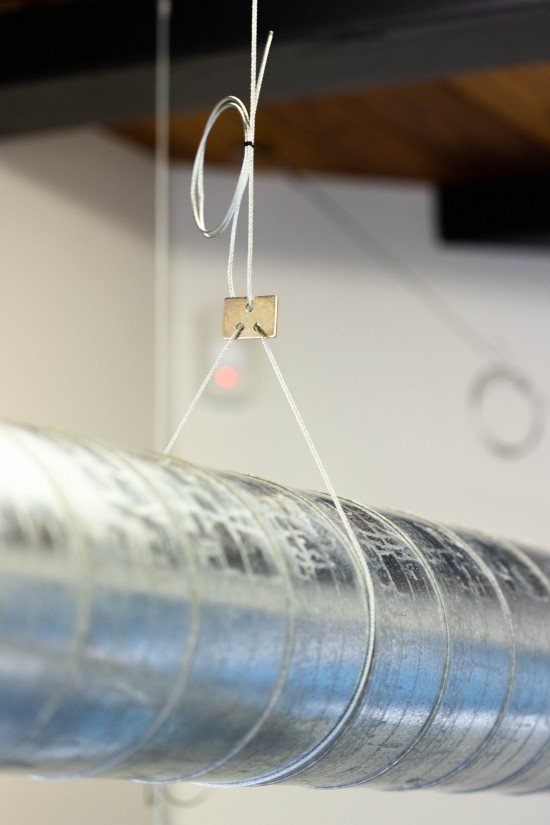

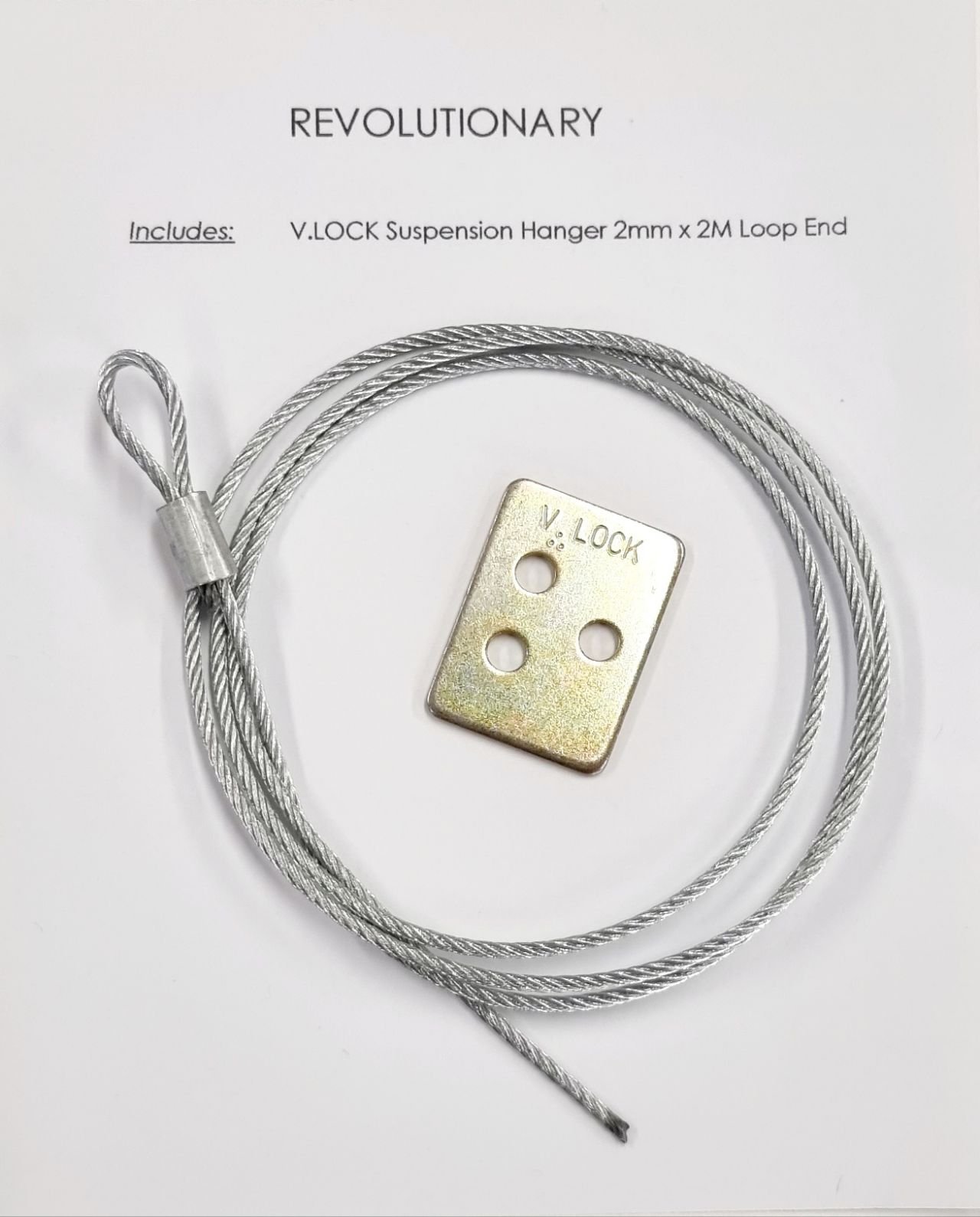

So here we've got some pictures of V-lock being used in seismic bracing and actually in installing the suspension.

Just a quick point on anchors to underline what Kayl's already said, they're often nearly always the weakest point in seismic design. Many improvements have been made in the past 10 years to improve seismic resilience in anchors. All concrete base materials in seismic zones should be assumed to be cracked. The drop in anchors should not be used. I was quite shocked four months ago, travelling around sites and suppliers in Australia to see M10 knock-in anchors being used even now.

They were just used outlawed back in 2010 in New Zealand. The issue is they're an expansion anchor and generally when they're installed, they're installed in parallel lines to suspend the ducting or cable tray and are drilled into parallel lines. So the earthquake hits, the concrete cracks and it cracks along where those anchors are. It's an expansion anchor, it loses its integrity, it simply drops out along with the services.

So what does V.LOCK do?

Turning our attention to the MEPF contractors, the issues they're facing day to day.

The two key points I would say are, there are unclear specifications which have little or no reference to seismic design being required or it's just a one-liner. Australia is in a transition time and some contractors are allowing for some seismic design and the product install and the inspection and sign-off and some are not. This creates an uneven playing field. So the contractor that allows for it, he misses the job. The contractor that wins the project is picked up at the end of the job with no seismic and he is forced to do it, making it a grudge purchase. So we help the contractors allow for and install a seismically compliant project so we don't end up with a mess as shown here.

This is a building in Wellington, New Zealand. It was a project we were engaged to retrofit after the Seddon earthquake in 2013. Now bearing in mind it had previously been signed off as complying to code, but there was no seismic design or bracing in the building whatsoever. The first task we had to do was to - what we call field mapping, to understand where the services were routed so we could design the seismic bracing, including considering the clearance requirements.Suffice to say, it's a lot easier to do this when the project's being built.

As a side note, this building was again damaged in the Kaikoura earthquakes in 2019 and it's since been demolished. Our retrofit was completely sound with no failures when inspected after the 2019 earthquakes, showing that proper design, installation and inspection works.

So we designed, supplied, oversaw the installation, signed off on this job.

It just gives you some idea of our capabilities and experience. Looking forward to roles and responsibilities, the architects, the engineer of record, the MEP designers and contractors, they need to develop and enforce specifications spelling out seismic requirements at time of tender. A clearly defined submittal process requiring seismic restraint calculations, layouts, plans and quality assurance inspections should be included.

The structural engineers should provide all of the necessary seismic criteria along with a document clearly showing locations of seismic separations on the drawings, along with design displacements. A document clearly anticipating drifts between the floors. So this helps the likes of our friends at KCL to quickly have the relevant information when doing their seismic design for the services.

So Conform, KCL and V.LOCK working together help the contractor carry an accurate dollar amount at time of tender. That involves quoting, design and supply. Together we take the complexity and mystery away from the contractor and make what is a relatively new difficult issue for them easy. So we can become involved during the design phase, during construction or even after all the utilities have been installed.

Together with Conform and KCL we determine the minimum quantity of material and engineering necessary. So the process. This is our specialty. Vaico has 14 years experience and hundreds of completed projects from hospitals to warehouses, shopping centres on our portfolio. We used to be a one-stop shop providing design, product supply, installation and sign-off. Basically soup to nuts.

Again as the market evolved, more and more engineers in New Zealand started doing designs and I realised they were doing it quicker and cheaper and better than I was.So we took our experience away and created products that were rated that any engineer could specify and we were at a price point in the market that was oftentimes half that of what was currently available. The main product being our V.LOCK.

Secondly we wrote our own software enabling us to very quickly quote any project to give the contractors two key numbers at tender time. One an estimation of how much the engineering will cost and two an estimation of how many V.LOCK braces will be required. We're constantly quoting within 10% of what's finally designed and installed on the project so it's very accurate.

And we break these two numbers out to give transparency to the contractor. Again an evolution of the market that's happened in New Zealand which is new in Australia. Typically these two dollar amounts are included as one figure currently. In Australia it allows margin to be hidden which in turn drives up the cost of the contractor.

Once the quote's accepted we push the design off to the engineer with seismic design ability such as our friends at KCL who finalise the drawings. We receive the mark up plan set back at which point we count the braces and Conform our distributor dispatches them to the contractor.

So just a final design note, we have concentrated on suspended services. However we do need to also consider the following. There's anchor calcs for floor and wall mounted equipment. Seismic certification for example, shake table testing of critical equipment such as generators at a hospital.

Engineer designs for anchorage and flex of system risers and drops to accommodate drifts between floors. Thermal pipe stress analysis. Flex joints at equipment or transitions. Flex joints at building seismic joints. Gravity vertical support engineering. And seismic control of vibration isolation systems.

So with that I'll wrap up. Thank you all for listening. Trust there was something touched on there that's useful to you and I'll hand back to Amanda.

Thank you very much.

End of Second Speaker

Amanda: Thank you.

Thank you for those great presentations from Kayl Byrne and Milton How.

So it's now your turn to get involved. Please ask our speakers questions. This is your opportunity to do so via the YouTube chat box and who you question you like it to be directed to. And also thank you to everyone who submitted questions whilst registering.

Q&A Section

Question: Are V.LOCK products tested to meet Australian and New Zealand Standards?

Amanda: I might start with you Milton. We've had a question that's come in about V.LOCK asking, is the V.LOCK product tested for Australian and New Zealand standards? Milton.

Milton: Yes, thanks Amanda. That's a good question. Yes, the V.LOCK product is independently tested by, it's a New Zealand accredited IANZ laboratory. Both IANZ and NATA are recognised as being equivalent by the International Accreditation Corporation which is the ILAC. We've also had testing done by an ICC accredited laboratory in the USA.

Question: How does the V.LOCK respond when the load is removed from the wire rope and lock?

Amanda: So before we bring Kayl in, the question's come in, I can see how the V.LOCK works when under load, but what happens if the load is taken off the wire, rope and lock? Does this release the wire rope? Milton.

Milton: So even when the load is completely taken off V.LOCK, the wire rope remains securely locked in place. This was particularly important and one of the features that was considered when we designed the V.LOCK system. Another point of interest to the engineers is that when the V.LOCK is tested to destruction, there are two things that happen:

The first thing is that the plate starts to deform and secondly the wires break. So if there is a moderate or severe earthquake, you can actually physically see with your eyes if the cables have started to fray or there's any damage. There's a lot of other products on the market that actual wire is hidden inside a casing, it's hard to inspect. So it's just, it was by default that happened, but it is good after an earthquake you can physically inspect it.

Question: Does equipment need to comply with AS 1170 standards, or can we use alternative standards like IEC for machinery?

Amanda: Thank you Milton. And Kayl, bringing you into the discussion, we've had a great question that's come in from Marcus.Marcus is watching in New South Wales.Good afternoon to you. And Kayl, in how far does equipment supplied need to comply with AS 1170? Since AS 1170 is written for buildings, is it difficult to transfer requirements to other machinery? Can we use other standards such as IEC? Kayl?

Kayl: Okay, so if we're considering, sounds like most likely a piece of mechanical equipment here, which is going to be of particular importance to those IL4 structures.So there may not be an Australian standard that directly deals with seismic performance of that equipment. So you would be looking towards either, so we can get the performance requirements from our code and we can get the loading from our code.So I'd recommend going there. So the piece of equipment itself would either need to be assessed by the manufacturer, so they'd have their own shake table testing. Or if there is a relevant overseas standard, then you would be drawing upon that, but applying our loads and our performance requirements. That would be a recommended approach.

Amanda: Thank you. Thanks for that, Kayl.

Question: Is V.LOCK stainless steel and can withstand for harsh climates and coastal areas in Australia?

Amanda: Milton, just back to you. We've had a question that's come in saying, "Australia has a very harsh climate and a lot of areas exposed to salt on the coast. Is V.LOCK available in stainless steel?" Milton?

Milton: Yeah, the short answer is V.LOCK is available in stainless steel. In fact, the integral V.LOCK plate is very easily produced in stainless steel, which is then packaged up with the stainless steel wire, crimps, and retrofit end fittings. So yes, we can do that.

Amanda: Thanks. Thanks for that.

Question: Who is responsible for seismic restraint: mechanical or structural engineers?

Amanda: Kayl, we've had a question that's come in again from New South Wales, from Antoine, asking, "Kayl, is seismic restraint part of a mechanical engineer scope or a structural engineer?" Thank you, Antoine.

Kayl: Okay, now I might be a little bit biased here, coming from a structural engineering background, but I suppose we do see it as a structural toolset or knowledge that's being applied. So I would probably recommend that approach.

And from a compliance or certification side of it, to be honest, I probably don't have the exact legal answer as to whether a mechanical engineer can sign off on that, but I would probably just start with that recommendation that it's more of a structural engineering skillset that's being applied.

Question: What are the seismic requirements for CW window design?

Amanda: Thanks, Kayl. And just staying with you for the moment, we've had a question come in from Vijay, and Vijay is in Victoria. Good afternoon to you. Asking you, Kayl - What are the requirements for facade CW windows design compliance to seismic?

Kayl: Okay, yeah, so if we're talking about facades, glazing systems, etcetera, which may or may not be sort of included into a partition's design, these are commonplace being engineered for, certainly for wind loading every day of the week. So your out-of-plane loading is most likely going to be governed by wind for items such as that. And the engineer involved should also have a handle on the seismic load. Potential for the in-plane loading to maybe have some sort of seismic governing case, but most likely it's going to be wind. So that, we wouldn't identify that as an area of a sort of a higher risk, such as some things that have been overlooked.

Facades probably fall into a category that is currently being rigorously engineered. So we'd see probably less risk there. Definitely would be considered, and possibly those in-plane situations, maybe seismic governing.

Question: If there's no Geotech report for a building, how can one determine the seismic parameters needed for engineer's seismic calculations, like importance level, probability factor, KP, hazard factor, Z, site, and subsoil class?

Amanda: Thanks, Kayl. And then just staying with you again, we've had a question come in from Arshia, asking you, "Kayl, if there is no existing geotech report for a building, what is the best way to find required seismic parameters for engineer's seismic calculation, such as importance level, probability factor, KP, hazard factor, Z, site, subsoil class?" Your thoughts, Kayl?

Kayl: Yeah, so those are a few of the parameters. The key parameters we need to do a load assessment. Generally there is a geotech report that exists, and asking in the correct places will often yield good results. You know, taking it back up through the food chain of contractors or whoever you may be engaged with, and you most likely would be able to turn up that report.

In terms of things like hazard factor, etcetera, they are outlined in the standard using the maps that are available in there for depending on the location.And I would also suggest that if you did have a closer look at those soil classifications and you do a little check to see which one gives you the most severe answer, you might find that there's a particular category that is applicable in most situations, I suppose. Thank you.

Amanda: Thank you.

Question: What advancements do you expect in seismic bracing technology?

Amanda: And just bringing Milton back in, Milton, you know, in your presentation, can you just talk about what you think are some of the trends we're going to see over the next few years? How do you think the technology will progress?

Milton: Yeah, that's a good question. I guess we have seen a little bit of it here in New Zealand, innovation happening, which we're trying to bring to Australia. You will find there will be more engineers that will specialize in this area of non-structural seismic design, I would say, probably lacking that in Australia. And I think this particular forum here is very important to get the word out, because that's where the compliance starts is with the engineering fraternity. And from there, it trickles down.

The anchors, there's been a lot of development in the past 10 years I touched on, and that's a good thing. And yeah, it's just more innovation like the V.LOCK products that are getting rated products out to the contractors at a price point. I'm sure there'll be more to come. Thanks.

Question: What advice would you give to our engineers to find out more about V.LOCK?

Amanda: Thanks, Milton. And for a communication understanding, what advice would you give to our engineers to find out more about the product? Where do they need to go?

Milton: Well, we have our own website, which has all our products with the ULS ratings in there. What Kayl touched on earlier, the particular documents need to be looked into. And there are some very good resources out of California in particular, like our code, a lot of it comes from initially the Californian code. And again, the market has evolved even further in the state of California. So there is resource if you want to dig into it a bit.

Amanda: Thanks. Thanks for that.

Question: How do structural engineers in Australia accommodate the S8.1 requirement for design and inter-story drift when no values, ISD, ULS or SLS are provided in the structural specifications?

Amanda: Kayl, a question that's come in from Jordan this afternoon. Good afternoon, Jordan. Asking, how do structural engineers in Australia accommodate the S8.1 requirement for design and inter-story drift when no values, ISD, ULS or SLS are provided in the structural specifications? Kayl, your thoughts?

Kayl: Similar to the geotech report, asking in the right places might actually yield those values for you, particularly if you sort of make it an important issue. So definitely another side of the design allowing for inter-story drifts.

I would also suggest that if we have a look in our relevant buildings code, particularly the concrete building code, we're going to have upper boundaries for the allowable inter-story drift. And we can just apply that upper boundary would probably be the safest place to start. That's common practice in both Australia and New Zealand.

Question: Are there any shot-fired anchors with ETA C1 or C2 ratings available in Australia?

Amanda: Thanks. Thanks, Kayl. And Jordan has gone on to ask you too. Thank you for watching, Jordan. Kayl, are you aware of any shot-fired anchors with ETA C1 or C2 rating available in Australia?

Kayl: Yeah, definitely an area of interest. Again, the C1 and C2 is becoming more critical. I don't currently know of any shot-fired fixings that achieve that. I don't believe they're available. I have possibly heard a rumour here or there that certain manufacturers are aiming to bring that to market. And it's possibly something we'll see, particularly for light-duty applications. So maybe that's a bit of a watch-this-space type answer. So not currently any that I know of, unfortunately.

Question: How does seismic bracing apply to ceiling or floor-mounted components below ground level?

Amanda: Thank you. Thank you, Kayl. And just staying with you for the moment, we've a question that's come in from Nick. Good afternoon to you. Asking, "How does this apply to parts components instructions below ground level that are ceiling mounted or floor mounted?"

Kayl: So AS1170.4 gives us our equivalent static forces, and they start from ground level and move their way up, and they're based on the building's response to that seismic event. If we have a structure that's below ground, its response is essentially that of the soil itself. So we can more or less take that sort of ground level factor.

And everything else is business as usual, essentially. So you do still have a force that needs to be accounted for, and we can still retrieve that from the code in the same way. So yes, bracing would commonly need to be provided.

Amanda: Thank you. Thank you.

Question: During refurbishments in buildings lacking seismic bracing, do services contractors only install bracing for the items they directly work on?

Amanda: And we've had a question. Has it been directed to anyone in particular? So who wants to pick this up? It may be Kayl. It's coming from Pranitesh, and it's an interesting question asking, "What is the responsibility of the services contractors working on refurbishments within existing buildings with no seismic bracing? Installing seismic bracing to only items that have been touched?" Thank you, Pranitesh. Who'd like to pick that one up? Kayl?

Kayl: Okay, so, yeah, that is actually quite a common occurrence, because we're often...Building services are often being upgraded throughout the life of a building, replaced, upgraded, etcetera. And essentially, we'd bring it back to that level of compliance. You know, similar, if you were going to add a renovation to the actual building structure, or, you know, part of penetration somewhere or something like that, generally, you're going to need to make good on anything that you interact with or connect to in that building.

So, even though it might be an older building, something from before any seismic loads were considered in Australia, in order to be, to the best of my knowledge, in order to be compliant, you're still going to have to install in accordance with the standards. And it's something that comes up quite frequently. So, the recommendation would to be do it as per usual, and anything that's part of that scope of work should be assessed for the seismic case.

Question: Which one is preferred for seismic design based on AS 1170.4, acceleration method or simple method?

Amanda: Thanks, Kayl. Thank you. And we've had a question that's come in asking, "Which one is preferred for seismic design based on AS 1170.4, acceleration method or simple method? Simple method gives very conservative design and is not cost effective sometimes." Is that one for you, Kayl?

Kayl: I'd say that question more or less sums it up. It is sometimes not cost effective.However, it is still a very powerful tool, and it's going to give a safe result. So, recommendation would be to try both and see what gives the most practical solution.

Amanda: Thank you. Thanks, Kayl.

Question: In what circumstances should rod stiffeners be employed in structural design?

Amanda: And Milton, we've had a question that's come in asking you, "Under what cases should we use rod stiffener?" Milton.

Milton: Yeah, so that would only be required when the threaded rod gets to longer length, and typically in Australia we would be looking at something like 750mm long. Over that, we would start to rod stiffen it. You can confirm that, Kayl.

Kayl: Yep, that's it in a nutshell. So from an engineering perspective, we can see we've got a nice equilateral triangle there with a tension member on the hypotenuse, so we can easily resolve the compression in that member, and we're essentially just giving it a bit more stiffness to handle that compression, and depending on the length, that stiffener detail could change. But yeah, Milton hit the nail on the head there, I think.

Question: Do pipes less than 25mm, grouped on a Unistrut hanger system without individual support, require bracing according to 8.1.4b, A?

Amanda: Thank you. Thank you. We've had a question that's come in from Derek. Hello, Derek. Asking, saying, "8.1.4b, A, for pipes less than 25mm but grouped on a Unistrut hanger system would require bracing as they're not individually supported." So it's more of a statement, but would you either of you like to add to that or expand on that?

Kayl: Yeah, so we've discussed that sort of list of exemptions there for the Australian standard, and I would say that yes, that's right, it does only apply for individually supported services and distribution systems specifically, and again, sort of use those exemptions at your peril. They may or may not be applicable for your particular case, and I would suggest that that sort of statement of having multiple services grouped on one support system, whether a typical trapeze it's often referred to, is more likely to be in that braced category.

Again, it is a bit of a case-by-case engineering assessment analysis that can be made, but you're not going to be able to just tick a box and put that into an exemption category like you can with, or possibly can with, some items.

Question: Should MEP consultants rely on structural engineers or seek certification to determine if seismic restraints are necessary?

Amanda: Thanks, Kayl. Questions come in from Ryan, asking, "What is the process MEP consultants should follow in determining if seismic restraints are required? Rely on structural engineer or certify to advise?" Kayl?

Kayl: Again, might be a little bit biased in this category, but I would recommend approaching a seismic consultant who can answer those kinds of questions. Generally, you're going to be able to get some free advice up front pretty easily just with a phone call, and also that kind of thing could go directly to someone like my colleague Milton, who can also assist with those sorts of things. Certainly, as Milton mentioned earlier, the market is going to progress so that this design is being done more up front, along with sort of the principal consultants, as it is done in New Zealand, and I think we will see that happen over the next few years in Australia.

Amanda: Milton, do you want to add to that?

Milton: Yeah, I think that's a good point, and that is typically what we see, particularly on the buildings of importance. When the tender documents come out, there's a full design done, so all the contractors are pricing on a level playing field. That said, once they win the project, that design will oftentimes change and be tweaked. It won't be what's actually installed, but the money's allowed, and it's front-footed that this needs seismic, it needs to be designed, it needs to be installed, it needs to be signed off.

Amanda: Thanks. Thanks, Milton.

Question: Who provides certification for seismic non-structural components?

Amanda: The questions come in for you, Kayle, from Fimba, and Fimba's in Queensland. Good afternoon to you. Thank you for watching. FIMBA is asking, "Who actually provides certification for seismic non-structural components?" Kayl?

Kayl: So, most commonly, that's going to be done by a seismic consultant, such as us, and we touched on before that we see it as a structural engineering knowledge being applied. The critical thing is that it does get done, and that's what we're here today to discuss, is that it's not something that can just get ignored, and it's probably not going to help everyone for just blanket exemptions to be applied or over-applied. So yeah, we certainly sort of see it coming back to a seismic consultant at the end of the day. Yeah.

Amanda: Thank you. Thanks for that.

Question: Do hot water plants have specific seismic restraint requirements?

Amanda: And we're sort of getting towards the end of the session, and I'd like both of you to do a bit of a sum-up, so take-outs for our viewers. But just a quick question Peter has put through. Thank you, Peter, asking, "Is there seismic restraint requirements for hot water plants?" Is that one for you, Kayl?

Kayl: We won't dive too deep into specific cases, but certainly something like a water tank, or a hot water, we need to account for that lateral force. If it's got no load path, then it's going to slide or tip over, so you're going to need to do an overturning check, sliding check, nothing too specific. And it could be restrained through a variety of different methods, whether holding down the base or adding support to the top of the unit, whatever may happen. We can, you know, it just sort of depends on the practical side, whatever application you have. Yeah.

Amanda: Thank you. Thanks, Kayl.

Wrapping Up

Amanda: And Milton, as I say, if you could just sort of give the audience what you think are sort of the five big takeaways from today, or the key message you'd like to get across to our audience to support and assist them going forward.

Milton: Okay, thanks very much. I guess we're talking to engineers today, but I tend to think of it from the contractors' point of view and what they're facing.

One of the things I was taught by a company called ISAT in California is, with seismic restraint, the devil is in the detail. You can't put a blanket rule over everything, but you can boil it down to three things. One is you need a proper design, and you need the rated products, the correct products from the anchor all the way through the load path to be installed correctly. And then thirdly, you need inspection.

And when you have those three things, you have a compliant project delivered. If one of those things is missing, it's like a three-legged stool, the chair tips over. So those three things are critical. And that's what I would like to get. I would like to get the engineers who are listening today to be getting their specs more robust, so it's in front of the contractor, and work towards getting a design done at tender time. But it's just that I'm sure it's going to evolve more quickly in Australia than it did in New Zealand. So there's a lot of lessons learned here that we can share with our friends over there.

Amanda: Thanks, Milton.

Amanda: And, Kayl, can I just ask you to do the same after, you know, what we've been talking about today and your presentation? What are the key takeouts you want to leave with our audience? Because we've covered a lot of ground today.

Kayl: I'd really echo that. The most powerful tool we have today is your specification, essentially. So please continue to flesh those out. The more information you can give up front is going to ensure that the contractor has a better chance of getting it right. In particular, that seismic rated anchors. So that is an Australian standard. And if it gets into the specifications, we have a much better time of getting it installed. The reality is I go to sites several, very frequently, and I see buckets and buckets of these knock-in anchors that are no longer compliant being installed to buildings.And they are highly likely being installed to your designs. So even if seismic has been completely ignored, someone is still installing your service. And it's most likely being, it's very possible that your service is being installed on an anchor that is not safe or suitable for a seismic load case. So all it would take is possibly one line in your specification, on your note sheet, on your standard details that says, "Hey, seismic rated anchors," and also ensure that you've got it done to 1170.4. That's going to go a really long way. So I think the seismic consulting will eventually get ahead of the contractors. But the reality is it's not, and it's going to take years to get there for most situations. So please continue to flesh out those specifications.

Amanda: Thank you. Thank you, Kayl.

Closing

Amanda: On that note, as always, we've run out of time. I'd like to please join me once again in thanking Kayl Byrne and Milton How for their time and input. I'd also like to thank Engineers Australia's industry partner, Conform Group, for their support.

It would be great to get your feedback as always. So if you could please complete the short feedback form, which is linked in the description box below. It only takes a couple of minutes, and it helps us to improve and plan for future sessions.

Thank you again for joining us, and I look forward to seeing you again at our next Thought Leaders event.

Good afternoon.

Thank you.

Traditional vs. Revolutionary

Traditional Suspension

Hot Works permits & cutting / grinding stations required

Multiple ascent & descent times on Lifts or Ladders

Increased Health & Safety risks

Logistics of getting parts to install locations (heavy / long lengths / crane / specialist equipment)

Time consuming & multiple tools required

Revolutionary Suspension

Up to 85% faster installation time

No measuring, cutting or grinding of steel parts

Simple to use & fully height adjustable

No Hot Works permit or cutting station required

Significantly less parts providing major cost savings on materials

Significantly reduced Health & Safety risks

Simple logistics on site

Are you suspending building services?

See the V.LOCK difference. Make the change

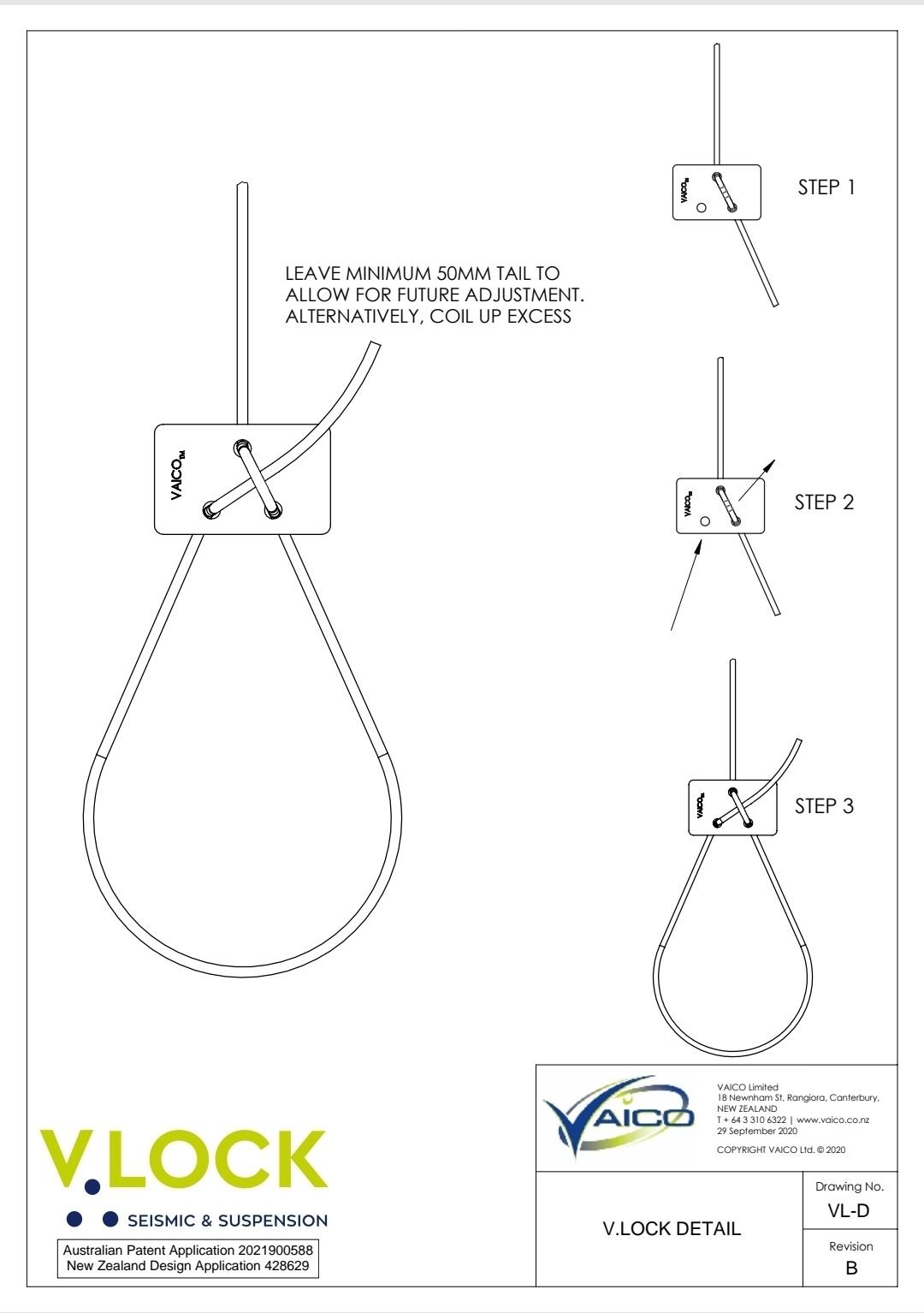

V.LOCK Suspension in 3 easy steps:

Secure the V.LOCK hanger to the structure (various anchor options available to suit different structure types).

Loop the remaining wire around your services (duct, cable tray, trapeze, etc).

Create an adjustable loop with the V.LOCK plate and set at the desired height.

Job done.

LOAD RATED, TESTED & SPECIFIED BY INTERNATIONAL ENGINEERS

Download Loop End Spec Sheet

Download 90deg. Angle Bracket End Spec Sheet

Contact us here for a discussion, pricelist and sample

Call us on +64 3 310 6322 or email sales@vlockglobal.com

AWARDED AUSTRALIA INNOVATION PATENT IN 2021

OTHER PATENTS PENDING

New Zealand Registered Design No. 428629

About the V.LOCK Product 💡

The V.LOCK Seismic & Suspension product was born out of adversity, and developed and refined with basic first principles at the forefront of the development.

The V.LOCK Seismic & Suspension product was born out of adversity, and developed and refined with basic first principles at the forefront of the development.

V.LOCK was developed by one of our staff members with basic tools and patience, bringing about a product that is user friendly and cost-effective.

Because of this simplicity, the V.LOCK product in some cases has reduced the cost to half the market rate ( when compared to competing products/solutions)

This simplicity has also translated into a highly effective yet basic manufacturing process, allowing the V.LOCK product to be produced in high volume anywhere in the world to our exacting standards, while reducing down-time, freight and importing issues.

Now with distributors and merchants worldwide V.LOCK has been a huge success.

V.LOCK has a Registered Design and has been granted Patent No 2021107288, with other Patents pending.

Take your pick NZ & Australia

A true game changer, firstly on install speed and more importantly cost.

A true game changer, firstly on install speed and more importantly cost.

V.LOCK is a doubled edged sword 🗡

A common question....

Q. Can I use V.LOCK Suspension and still comply with seismic requirements?

A. Yes, V.LOCK Suspension can be used for intermediate gravity supports. Where seismic restraints are designed and engineered, use a traditional rod hanger or trapeze. With V.LOCK Seismic added to the solid support locations, your system complies with seismic requirements.

Talk to us today to find out more, and how we can coordinate seismic and suspension on your projects.

The KISS principal

KISS, an acronym for keep it simple, stupid, is a design principal noted by the U.S. Navy in 1960.

KISS, an acronym for keep it simple, stupid, is a design principal noted by the U.S. Navy in 1960.

The KISS principal states the most systems work best if they are kept simple rather than made complicated; therefore, simplicity should be a key goal in design, and unnecessary complexity should be avoided.

Helping Out at Wai Ariki Hot Springs & Spa

The Wai Ariki Hot Springs & Spa is a luxury spa and wellness centre set on Rotorua’s lakefront, and is currently under construction.

The Wai Ariki Hot Springs & Spa is a luxury spa and wellness centre set on Rotorua’s lakefront, and is currently under construction.

Situated on the shores of Lake Rotorua, Wai Ariki Hot Springs & Spa will deliver health and wellness experiences infused with authentic Te Arawa and Māori culture, to create a rejuvenating experience to remember and share.

With Māori culture at its heart, the development draws on the 650 year legacy of the local Maori tribe, Ngāti Whakaue’s and Rotorua’s famed spa heritage.

Its name, Wai Ariki or “chiefly waters”, is a reminder of the origin of Rotorua’s healing thermal waters, which have drawn visitors to the city for more than 130 years.

Wai Ariki’s unique features combine with therapeutic mineral waters to deliver a world class bathing, spa and wellness facility that provides a place to relax, sustain and heal.

Developed by Pukeroa Oruawhata, with design advice from acclaimed spa and wellness provider Belgravia Leisure, Wai Ariki will be necessary to visit, and leave a desire to return.

#vlockglobal V.LOCK Global is pleased to have been trusted by the contractors to help coordinate seismic design/engineering/V.LOCK seismic bracing for the mechanical services. We look forward to visiting this unique project when it's complete!

Contact us sales@vlockglobal.com to see how we help you simplify and save on #seismic & #suspension

Hanley Farm Primary School Project.

We're always impressed with The Remarkables mountain range (Kawarau). Likewise, its impressive the way the designers, architects, builders and the construction teams can deliver a project to blend into such a beautiful backdrop.

We're always impressed with The Remarkables mountain range (Kawarau). Likewise, its impressive the way the designers, architects, builders and the construction teams can deliver a project to blend into such a beautiful backdrop.

TE KURA WHAKATIPU O KAWARAU

#vlockglobal Vaico V.LOCK Global was pleased to have supplied V.LOCK for the Seismic & Suspension of services on this Hanley Farm Primary School project.

The Remarkables mountain range runs exactly north south (one of the two mountain ranges in the world which run directly north to south, the other being the Rockies), and was formed by the pressures of tectonic plates moving along the fault line that runs the length of the Southern Alps. The faulting and folding of schist rock has created the awesome near vertical rock faces that dramatically surround Jack’s Point, near Queenstown New Zealand.

V.LOCK Global Helps Out With The New Countdown Balclutha Store

The local community has poured through the doors of the brand new, state-of-the-art Countdown Balclutha store this week, after watching 12 months of construction.

The local community has poured through the doors of the brand new, state-of-the-art Countdown Balclutha store this week, after watching 12 months of construction.

The $18 million dollar development is the first Countdown in the area and has a number of key sustainability features like electronic shelf labels to reduce paper use, bike racks for customers, a transcritical refrigeration system, and doors on fridges. It's also another important milestone in Countdown's $50 million programme of investment in Otago and Southland, which will see a further four new stores or existing store renovation projects delivered over the next 12 months.

V.LOCK Global was pleased to have been the #seismic product of choice for the mechanical systems throughout. Contact us +64 3 310 6322 or email sales@vlockglobal.com to find out how we simplify the price and product proposition for your projects.

Congrats to all involved on another successful delivery.

Credits: Countdown Supermarkets

V.LOCK Global Seismic Product of Choice for Automall West

Automall West, a whole new experience in buying a new car, has accelerated into life inside the Indooroopilly Shopping Centre located in Brisbane, Australia.

Automall West, a whole new experience in buying a new car, has accelerated into life inside the Indooroopilly Shopping Centre located in Brisbane, Australia.

Buying a new car has gone up a gear. Automall West hosts seven new-car brands including Porsche, Jaguar, Land Rover, Ford, Volkswagen, Honda and Subaru with space available for events to show featured launch and heritage models and other brands.

Take a fly through the showroom here https://lnkd.in/dN8HqX6h

Keep an eye out for the black powder coated cable trays as you fly thru this epic Automall! Also spotted on the images below.

V.LOCK Global is pleased to have been the #seismic product of choice for the electrical contractor throughout. Seismic certification & Form 15 / Form 16 to suit QBCC requirements.

Contact us +64 3 310 6322 or email sales@vlockglobal.com to see how we simplify the price and product proposition for your projects. New Zealand 🇳🇿 Australia 🇦🇺

Photo & image credits: https://lnkd.in/dBbhSDgW & Automall West/Facebook. See more here: https://lnkd.in/dKBfPQgR